Sep 6, 2023 - 5 mins

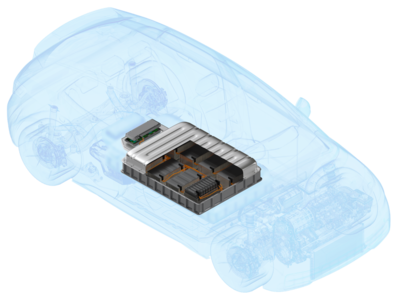

Batteries: The UV Advantage in Electric Vehicle Battery Manufacturing

As the demand for electric vehicles (EVs) continues to rise across the globe, the spotlight intensifies on the efficiency and sustainability of their core component: the battery.

Dielectric coatings are materials for insulation and protection that prevent electrical conductivity. The process of applying a dielectric coating to a battery involves several steps to ensure proper adhesion, even coverage and optimal performance.

Liquid dielectric coatings, typically applied through a spray nozzle and well-suited for complex geometries, are becoming a popular choice to protect and insulate battery cells. After the liquid coating is applied, the protective layer is cured to optimize its mechanical and electrical properties. Traditional thermal curing uses heat to harden the coatings. This process is energy-intensive and time-consuming. The heat can even damage the battery cell if the process is not closely monitored.

Enter liquid resins cured with ultraviolet (UV) technology—a promising avenue in the realm of EV battery production.

Offering rapid curing times, reduced energy consumption, and enhanced precision, UV technology is poised to revolutionize the manufacturing landscape, setting new benchmarks in EV battery performance and reliability.

UV technology can significantly enhance EV battery manufacturing in several ways:

1. Energy Efficiency: UV technology enables solvent-free curing processes, reducing the energy consumption by at least 60% compared to traditional curing methods. This translates to lower production costs and a more sustainable and energy-efficient manufacturing process.

2. Instant Curing: UV curing is a rapid process that enables instant drying and solidification of the dielectric coatings on battery cells upon UV light exposure. This quick curing time increases the production throughput, leading to higher manufacturing efficiency and reduced cycle times.

3. Ease of Application: UV-curable materials are typically easier to apply to battery cells, which streamlines the coating process. This ease of application results in more consistent and reliable coatings, reducing the risk of defects and ensuring better overall battery performance.

4. Improved Dielectric Properties: The use of UV-curable specialties, like Sartomer® UV-curable liquid acrylates, methacrylates, and photoinitiators can provide battery cells with excellent dielectric properties:

- Breakdown strength

- Volume resistivity

- Dielectric constant

- Dissipation factor

Good electrical properties enhance the insulation between the positive and negative electrodes, improving the overall safety and efficiency of the battery.

5. Enhanced Adhesion and Flexibility: UV-curable materials offer good adhesion to various substrates ensuring that the dielectric coatings remain securely attached to the battery cells even under challenging conditions. Additionally, the flexibility of UV-cured coatings allows them to withstand mechanical stresses and temperature variations during battery operation.

6. Scalability and Mass Production: The combination of low energy consumption, instant curing, and ease of application makes UV technology highly suitable for mass production. As the demand for EV batteries increases, UV technology can help meet production targets effectively.

7. Environmental Benefits: The elimination of solvents in UV curing processes reduces volatile organic compound (VOC) emissions, contributing to a cleaner manufacturing environment. There is also less waste in the production process given the precise control and speed.

Overall, UV technology is a compelling choice for the manufacturing process of EV batteries, and can enable improvements in energy efficiency, production speed, and battery performance.

Our Offer for EV Battery

UV-curable specialty liquid resins and additives for dielectric coatings

Sartomer® UV-curable acrylate resins and photoinitiators enable coatings formulators to address the challenges of this application: excellent dielectric properties, adhesion, flexibility and ease of assembly.

SARTOMER AMERICAS PRODUCT FINDER

Explore the AMERICAS product offering

SARTOMER EMEA PRODUCT FINDER

Explore the EMEA product offering

Battery Solutions by Arkema

Arkema has a wide breadth of offerings for inside and outside the cell, module and pack components, including binders for electrode and edge coating, LiFSI salts, cathode additives, and resins and polymers.

Collaborative innovation & expertise

Partner with us for your materials

Arkema's dedicated UV resin and additives development teams are available to help you achieve tailor-made materials to address your specific application challenges.CONTACT US