LOCA: UV/LED resins for liquid optically clear adhesives

Electronics, from our smartphones, computers, televisions, wearables or automotive screens, have become a modern day non-negotiable. Sustainable considerations beginning with the raw materials early in the design process can lead way to greater sustainability practices in a massive industry with significant environmental impact. As consumers begin to seek our options with better environmental impact, lower carbon emissions, and increased recyclability, technology advancements on the materials side can offer energy savings, bio-based content and performance benefits.

Liquid Optically Clear Adhesives (LOCA) are primarily used in the electronics industry for bonding displays to touch panels or cover lenses. They play a crucial role in devices where the clarity of the adhesive is essential for the function and aesthetics of the device, such as smartphones, tablets and touchscreen devices.

Properties of Liquid Optically Clear Adhesives

- Optical Clarity: Engineered to be highly transparent with superior light transmission capabilities. Crucial for maintaining the vividness and sharpness of display screens.

- Refractive Index: Fine-tuned to align closely with that of substrates like glass or plastic. Key to reducing optical losses from refraction and reflections at the interface where the adhesive is applied.

- Bonding Strength: Formulated to create a strong interlayer bond, significant for the structural integrity and overall tactile response of the device.

- Durability: Designed for longevity, LOCA resists environmental factors that can lead to degradation over time, such as yellowing.

- Thermal and Mechanical Properties: Absorb and dissipate stresses caused by thermal expansion or contraction as well as mechanical shocks or vibrations, which is vital for the protection of delicate display components.

- UV Curing: A characteristic feature of many LOCA formulations is their ability to be cured quickly under UV light, facilitating rapid and controlled adhesive setting during the manufacturing process. UV curing is solvent-free and low-VOC, and enables faster cycle time with lower energy consumption.

- Non-conductivity: Ensures that it does not interfere with the electrical functions of the device, maintaining signal integrity and operation.

- Gap Filling: Due to its liquid state before curing, LOCA can fill in minute gaps and surface irregularities, creating a uniform layer that supports consistent optical performance across the display.

UV-curable resins for LOCA

Offering specialty monomers, oligomers and dielectric resins designed for high-performance

Urethane acrylate oligomers

CN9021 and CN9018 impart excellent adhesion and flexibility to laminating and pressure sensitive adhesive formulation, especially those for glass.

PRODUCT HIGHLIGHTS

- Superior optical clarity

- Low haze

- Excellent adhesion to various substrates such as glass, stainless

- steel, and other plastics

- Good moisture resistance

- High elongation

Starting point formulations

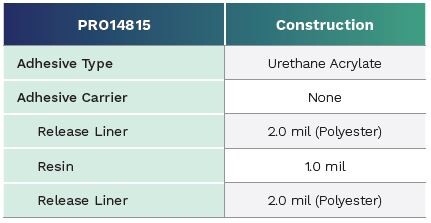

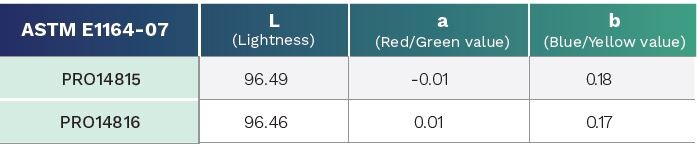

PRO14815 contains 76% CN9021 and PRO14816 contains 76% CN9018

LAMINATING PROCESS

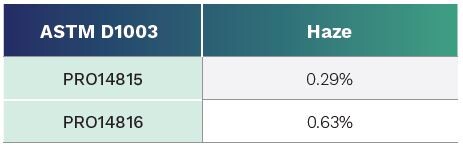

HAZE

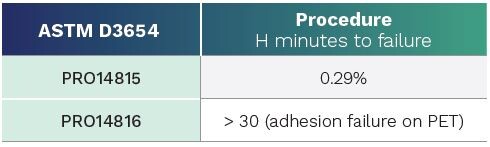

SHEAR ADHESION

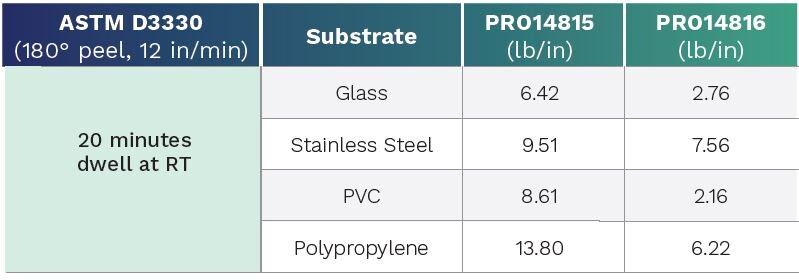

PEEL ADHESION

COLOR

TRANSMISSION

ASTM E903, D1003, and E284 Optical Clarity: 97% Transmittance at 380 nm and 99% Transmittance at > 400 nm